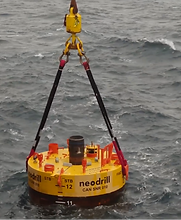

CAN-ductor

Mitigate common risks associated with conventional conductor installation with our patented technology.

The CAN-ductor is one joint of conductor integrated within the body of the CAN-basic. As with all CAN solutions, it is built at our workshop to be installed by a vessel ahead of rig arrival. The CAN-ductor includes all the features of the CAN-basic with even more cost savings and risk mitigation.

Equinor has purchased a licence to use the Neodrill technology under the brand name CAP-X, and the first use was on the Bauge field.

FEATURES & BENEFITS

Pre-rig well construction

By building CAN solutions onshore it enables us to ensure quality and complete tasks that would traditionally be done at higher costs offshore.

Unrivalled ability for shallow kick-off

CAN-ductor has an unrivalled capacity to facilitate shallow kick-off, having been field proven in the Barents Sea for a horizontal well with top reservoir at 250 m.

Independent of rig schedule to save rig time

The CAN-ductor is installed from a vessel ahead of rig arrival, and installation quality can be verified pre-rig arrival. This removes the 36” (42”) hole drilling, conductor running, and cementing operations from the rig schedule.

Verified load capacity

Load capacity is calculated onshore and verified during installation to ensure quality and integrity.

Simplified P&A operations saves 2-4 days

The CAN-ductor mitigates a series of common top-hole risks, as the rig only needs to cut the surface casing before leaving the location. A light vessel is then able to retrieve the CAN.

Easy integration of protection structures and flow lines

The CAN-ductor can be engineered with other CAN technologies for the ultimate subsea wellhead foundation.

Verified inclination

In all of the projects carried out to date, CAN solutions have a proven inclination of less than 1°.

APPLICATIONS

Exploration wells

Our CAN solutions are ideal for exploration since the conductor is recovered with the CAN it is only necessary to cut the surface casing, making P&A operations far more efficient.

Production wells

CAN technology reduces project execution time for production wells. Savings per well are generated from pre-rig well construction and pre-mounted equipment.